ROTARY MILKING PARLOUR

Whether it’s cow flow, milking or milking, the rotary milking chamber is designed for efficient processes and the highest performance. It is milked at 32-120 milking stops with an outstanding rate of manpower and milk yield, from medium to very large flocks. All components, no exceptions, are designed for maximum service life and highest reliability in 24/7 operation. The study area in the rotary milking room is perfectly organized. Each step is synchronized; open vision and free access to the udder, the mount handle, as well as the ergonomically placed milking head. In just seconds, cows are transported to smooth milking stops. Especially low-profile cabinets with smooth surfaces and round forms are made with cow anatomy in mind. For high milking comfort, thanks to a positioning lever without leverage force, the milking head can be placed individually for each breast. Cows stay comfortable with each round.

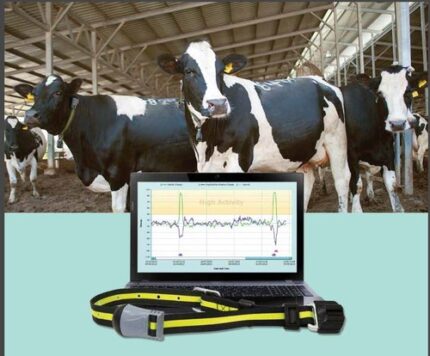

Everything comes together with the system in a highspeed network: Innovative rotary system control allows you to visualize and control processes in real time. The occupancy rate of the milking stops, animal data and current milking results are available at a glance on the touch screen for the controller. Identity systems recognize the cow when it comes to the platform. In the background, milking management is undertaken by milk control units and milk flow controlled automatic separation system.

Electric Fence Devices

Electric Fence Devices Insulators

Insulators Ropes

Ropes Other Equipments

Other Equipments

Milking Systems

Milking Systems Milking Machines

Milking Machines Cow

Cow Sheep & Goat

Sheep & Goat Spare Parts

Spare Parts Manure Magagement

Manure Magagement Cooling Tank

Cooling Tank Barn Equipment

Barn Equipment Farm Equipment

Farm Equipment Feed Mixing And Distributing Machines

Feed Mixing And Distributing Machines Solid and Liquid Fertilizer Spreaders

Solid and Liquid Fertilizer Spreaders Dump Trailers

Dump Trailers Animal Collars

Animal Collars

Reviews

There are no reviews yet.