MANURE SCRAPER

It provides a clean and healthy environment for animals by automatically stripping the manure accumulated within the animal shelter at regular intervals. It is designed depending on the structure of the barn.

TECHNICAL SPECIFICATIONS

Type: Chain-driven, mobile wing

Dimensions: 10 x 250 m

Number of tracks: 1-2 tracks

Number of drive units: 1 unit/

Motor power: 1.1 kW

Material: Hot dip galvanized

Chain/rope thickness: 13 mm

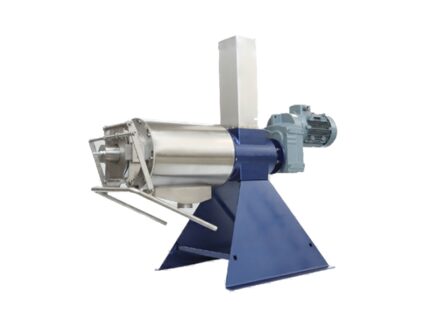

MANURE SEPARATOR

It is the machine that separates the liquid and solid components of the fertilizer from each other by mechanical compression method. There are two main reasons for the separation process. Increasing the fertilizer storage capacity. Adding economic value in both branches by separating the solid-liquid phase.

TECHNICAL SPECIFICATIONS

Capacity: 10-30 tons/hour

Material: 304 stainless steel screens and augers, including the tower.

Motor power: 5.5 kW

Platform: 100x100x3 mm profile, 3.5x1.5x3.15h

Control panel: 380 three-phase - with phase protector PARALLEL MILKING PARLOUR

Take advantage of all the advantages of the Parallel Milking (Rapid Exit) system technologically. Our company, which successfully implements parallel milking systems, supports high efficiency in milking project with high-tech solutions. The common Parallel Milking System is used successfully in many situations worldwide with a model size of up to 2x24

Minimum Waiting Time Animal placement is designed to provide access to the udder between the two hind legs. To facilitate the exit of animals, the exit doors are opened automatically. Chrome milk line is offered as a whole with improved vacuum pump, milking caps, milk meter,

inflorescence remover, electronic pulsator and computerized milking pane.

Animals are lined up side by side in parallel systems, the milker has to approach at a full 90 degree angle. The main advantage of the parallel system is the reduction of the milking tank length. Although it is not recommended in milking houses with a capacity lower than 2x12, Parallel System is preferred to prevent milking and vacuum line lengthening in larger capacity milking plants. Fast-outlet milking machines are popular with

enterprises with a large number of milking

animals.

RECEIVER GRUP

60 and 80 it used in Milking Rooms. Stainless steel collection boiler, 7000 and 14000 it/min transfer motor.liquid level relay (swich), consists of 1 O lt safety glass fan. Its task is to automatically transfer milking in the milking room to the cooling tank. The transmission engine is powered by 220 or 380 Volts of energy, and there is a manual discharge button in case the swich fails. A rubber pipeline that does not produce bacteria lies

between the transfer engine and the tank

Electric Fence Devices

Electric Fence Devices Insulators

Insulators Ropes

Ropes Other Equipments

Other Equipments

Milking Systems

Milking Systems Milking Machines

Milking Machines Cow

Cow Sheep & Goat

Sheep & Goat Spare Parts

Spare Parts Manure Magagement

Manure Magagement Cooling Tank

Cooling Tank Barn Equipment

Barn Equipment Farm Equipment

Farm Equipment Feed Mixing And Distributing Machines

Feed Mixing And Distributing Machines Solid and Liquid Fertilizer Spreaders

Solid and Liquid Fertilizer Spreaders Dump Trailers

Dump Trailers Animal Collars

Animal Collars